QL composting test technical report

Setup of chicken manure composting test

MIT CM (GHW-1) vs Probiodex and Flush

Formulation and microbe usage for test

Configurations of raw material and microbes input per Mt.

Test protocol

Raw Materials used

Chicken manure (dried)

Chicken manure (wet)

Sawdust

Boiler ash

Temperature and moisture records with chart

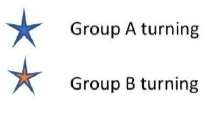

Daily Temperature Record (With illustrations)

Day 0

Treatment

1. Mixing

2. Spraying water

3. Spraying microbe

Day 14

Group A

Group B

Day 28

Group A

Group B

Day 32

Group A

Group B

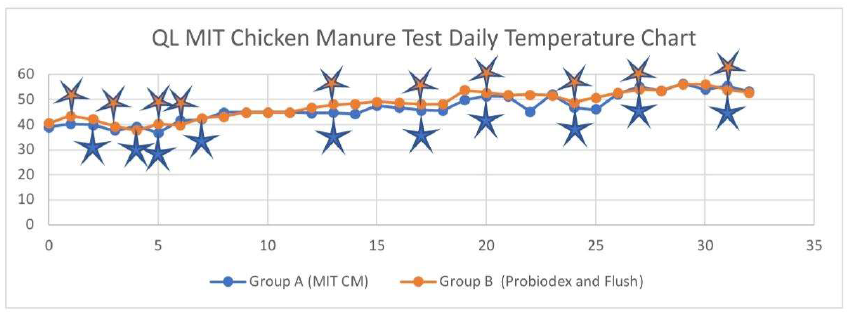

Daily Temperature Chart

Moisture content record

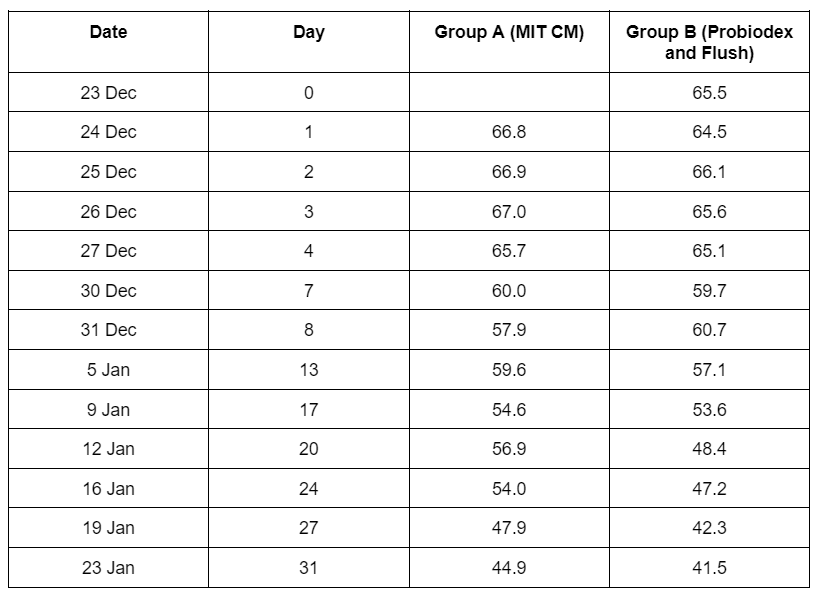

Moisture content chart

Comparison and Observation

Compare items

Temperature

Appearance

Odours

Moisture

CN Ratio test

Group A and B

No significant difference from both groups

No significant difference in colour and outlook.

The ammonia in groups A and B are at 20 ppm respectively. No significant difference from both groups.

Taking 10 sampling points, moisture content test results show that Group A content lesser moisture than Group B.

Group A has a lower CN ratio than Group B.

Group A (MIT CM)

Average temperature: 46.0°C

39.1

8.7 to 1

Group B (Pro/Flush)

Average temperature: 48.8°C

42.45

11.61 to 1

Conclusion

1. After 30 days of fermentation, it was found that there was not much difference between the two groups in terms of appearance and smell.

2. There is a significant difference in CN Ratio between the two groups(Group A is 8.7 and Group B is 11.61), which means that the ratio of raw materials is inconsistent when mixing. This can affect differences in the fermentation process.

3. The CN Ratio is obviously low, which is not conducive to the fermentation environment. It is recommended to increase the proportion of Carban in the raw material formula.

4. Due to the limitation of the fermentation site, the fermentation shape is elongated, which prevents the raw materials from being piled high, resulting in the inability to generate a high-temperature environment, which will affect the duration of the fermentation.

5. Large-scale machinery is used for stack turning, uneven turning work results in uneven moisture content. This will result in an uneven fermentation process.

6. The second batch of experiments will focus on CN Ratio, moisture content and configuration of raw materials.

7. The experiment will enter the second stage for re-evaluation (about 45 days).